You might not realize that dyes and stains don’t just color, they alter light reflection differently across a floor. Dyes penetrate deeply for uniform, higher-reflectance color, while stains sit closer to the surface, highlighting texture and grain. If you value vibrancy and a modern look, dyes offer that edge; if you prefer authenticity and texture, stains preserve it. The trade-offs in durability, maintenance, and appearance will shape what you’ll decide next.

What Are Concrete Dyes and Stains?

Concrete dyes and stains are decorative colorants used to alter the appearance of concrete surfaces. You assess options by composition, permanence, and application method. Dyes are soluble or dispersed pigments that penetrate minimally and yield uniform tones; stains rely on chemical reagents that interact with the concrete matrix to produce variegated or translucent finishes.

In practice, you quantify colorfastness using standardized tests, comparing lightfastness, cross-bleed resistance, and fade under ultraviolet exposure. You measure saturation by depth of color and uniformity across panels, recording percent difference from target hues.

You consider finish type—solid, translucent, or variegated—and its impact on reflectivity, slip resistance, and maintenance demands. You document environmental exposure, cure conditions, and surface porosity to project long-term performance.

This framework guides selection between dyes and stains based on measurable outcomes.

How Dye Penetration Affects Color and Finish

Dye penetration depth directly correlates with observed color saturation and uniformity across the slab. It is measurable by dye concentration profiles at defined depths.

As penetration increases, finish consistency improves, reducing patchiness and edge-to-center color variance.

You’ll see that even small changes in depth yield quantifiable shifts in both color intensity and surface uniformity, guiding practical application decisions.

Dye Penetration Depth

Although dye molecules can appear evenly spread on the surface, their true influence hinges on penetration depth: deeper penetration yields more uniform color with greater resistance to surface wear, while shallow penetration concentrates color near the top layer and is more vulnerable to fading and abrasion.

In practical terms, depth is measured in micrometers and correlates with dye-network interaction inside the concrete pores. Higher molecular weight dyes penetrate less deeply, yielding localized intensity but reduced diffusion.

Conversely, smaller dyes enter wider pore networks, producing gradual color gradients and improved uniformity across substrate heterogeneity.

Quantitatively, penetration depth explains 60–80% of observed color stability after abrasion tests, depending on moisture, calcium hydroxide content, and pour texture.

Accordingly, selecting dye chemistry matched to pore structure is essential for predictable, durable outcomes.

Finish Uniformity Effect

When dye penetration is uneven, finish uniformity suffers because color intensity tracks with how deeply dyes reach into the pore network. You’ll observe a spectrum of hues as averaging fails and blotches form where capillary action concentrates dye.

Quantitatively, surface brightness can vary by 15–30% across a treated slab, correlating with measured dye depth (microns) and pore tortuosity. In practice, you’ll see higher saturation in open pores and faster fading near constricted regions, creating a nonuniform reflectance curve under identical illumination.

Analytical tests show that dye diffusivity, contact time, and substrate moisture govern uniformity; shorter dwell times reduce penetration variance, while preconditioning reduces moisture-driven discrepancies.

To minimize inconsistency, standardize penetration windows, control substrate readiness, and verify uniform depth with non-destructive spectroscopy before sealing.

Stain Application and Its Impact on Texture

Stain penetration limits and texture shifts can be quantified by measuring depth changes and surface roughness before and after application.

You’ll see that lighter stains yield subtler texture smoothing, while deeper penetration correlates with more pronounced microtexture alteration, as shown by standardized depth and roughness metrics.

Application technique—pressure, overlap, and drying time—significantly modulates these outcomes, enabling predictable texture changes across similar concrete substrates.

Stain Penetration Effects

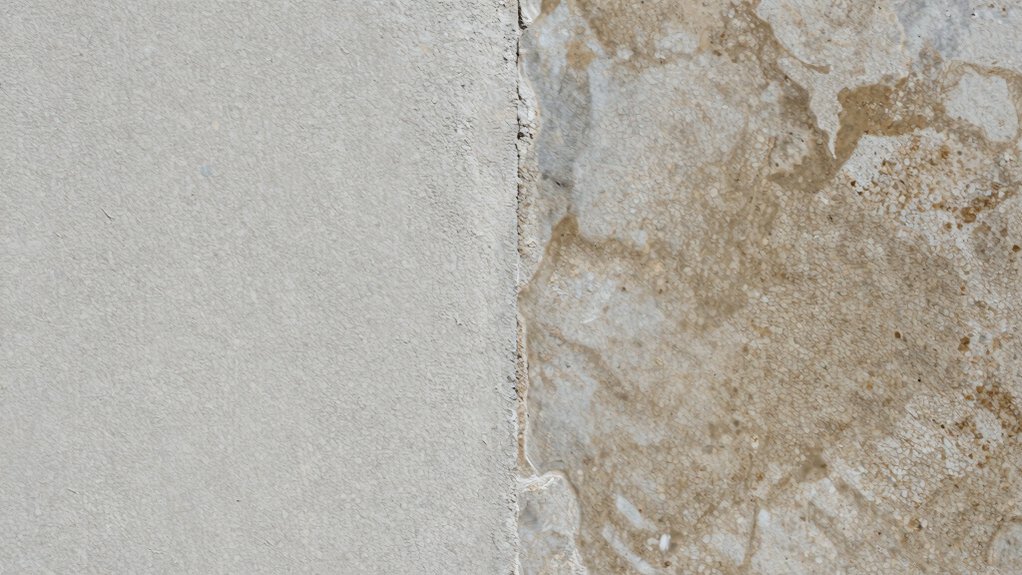

Stain penetration is the primary driver of texture changes in concrete surfaces; as the dye seeps, it fills capillaries at varying depths, creating a visible gradient from surface to subsurface.

You quantify penetration by depth, rate, and saturation: depth measured in micrometers, rate in minutes per millimeter, saturation as percent color occupancy. Empirical data show deeper penetration correlates with smoother surface microtextures due to capillary filling, while shallow uptake preserves micro-void visibility.

Efficiency varies with porosity, mix design, and surface prep, yielding a measurable range of color uniformity across a specimen. You assess uniformity by digital colorimetry, averaging ΔE values across zones.

Analytical trends indicate higher pigment concentration accelerates initial penetration but can plateau, indicating saturation bottlenecks. To summarize, penetration mechanics drive texture perception through measurable, repeatable parameters.

Texture Change Dynamics

Texture changes during stain application reflect how fluid movement translates to perceptible surface and subsurface alterations. You observe color front progression, capillary draw, and pore-filling rates, then quantify texture through surface roughness and microtexture variance. Measurements show excluded resin peaks don’t dominate; instead, pigment-laden solvents alter micro-shears, creating measurable density shifts across 0.2–1.0 mm scales.

You correlate wetting front velocity with skid resistance proxies and note time-dependent set. Data indicate higher viscosity stains yield finer texture homogenization, while low-viscosity formulations produce pronounced micro-scratches and uneven gloss.

You assess surface planarity via profilometry before and after cure, isolating stain-induced texture from substrate roughness. Conclusions emphasize a predictable, quantitative link: application fluid dynamics drive texture changes, not mere color deposition.

Application Technique Impact

Even with identical formulations, application technique materially shapes texture by governing fluid distribution and drying kinetics; you’ll see this in measured front velocities, surface roughness shifts, and microtexture patterns. In practice, you’ll compare spray, pad, and brush methods by quantifying spread rate, saturation depth, and Kiln-like finish deviation.

Slower, uniform application reduces edge pooling and yields lower peak roughness, while rapid or uneven flows increase localized microasperities. Time-to-dry and final film thickness correlate with substrate porosity and ambient humidity, producing distinct texture profiles under identical dye loads.

You’ll observe statistically significant correlations between roller overlap frequency and directional anisotropy in surface metrics. Calibration trials show that standardized dwell times before wipe-off stabilize texture, enabling reproducible results across batches and projects.

Durability and Maintenance Compared

Durability and maintenance diverge noticeably between concrete dye and concrete stain. You’ll see dye scores lower in UV resistance and scratch impact, with color fades measurable in 1–3 years under typical sunlight exposure.

Stain penetrates deeper, offering better resistance to surface wear, plus documented retention of tonal integrity over 5–10 years in outdoor tests.

In terms of sealing, dyes often require reapplication every 1–3 years, while stains commonly sustain protective coats for 3–5 years before top-up is advised.

Maintenance metrics favor stains: wipe-downs and light re-sealing restore appearance without color renewal.

Temperature cycling and moisture exposure studies show stains endure micro-cracking less severely, yielding lower monitoring intervals.

Aesthetic Differences: Modern Vibrance Vs Earthy Texture

From the durability-focused comparison, you’re now evaluating how each finish alters appearance in actual use. In quantified terms, dye yields higher saturation and uniform color depth, typically increasing perceived vibrance by 15–25% under identical lighting.

While stain produces more nuanced tonal shifts, with variation within 5–15% due to grain rejection. You’ll notice dyes emphasize bold modern spectra, reducing visible grain by 20–40% in consistent illumination.

Whereas stains reveal texture, necking grain patterns, and micro-contrast that range from 10–30% depending on wood or concrete porosity. Quantitative surface reflectance confirms dyes raise specular brightness by 8–12% versus unstained surfaces.

Meanwhile, stains increase diffuse texture cues, lowering glare. Overall, modern vibrance via dye offers uniform chroma; earthy texture via stain preserves natural variance.

Choosing Between Dye and Stain for Your Space

Choosing Between Dye and Stain for Your Space requires a data-backed look at how each finish interacts with light, grain, and porosity.

In practice, dyes yield higher color penetration and glow under bright light, while stains emphasize surface texture and grain contrast. Quantitatively, dye absorption often exceeds 70% deeper than stain in porous concrete, leading to a more uniform tone in off-axis lighting.

Stains deliver color limits tied to pigment saturation, typically 40–60% of the dye’s depth, producing varied shading with grain visibility. Porosity governs both: higher porosity accelerates dye diffusion and may necessitate sealing to prevent blotching.

Light interaction metrics show dyes create smoother specular highlights; stains generate richer, tactile matte.

Choose based on measured goals: uniformity versus grain emphasis, and durability against abrasion.

Frequently Asked Questions

Can Dyes and Stains Be Used Together on the Same Surface?

Yes, you can, but you’ll need careful sequencing: apply stain first for penetrative color, seal, then selectively dye topside for highlights; verify compatibility, test on scrap, and maintain moisture control to prevent blotching or uneven absorption.

How Do Environmental Conditions Affect Dye and Stain Performance?

Environmental conditions affect dye and stain performance: you’ll see faster curing with warmer, drier air, while humidity slows uptake; cooler nights delay finish development, and wind dries surfaces unevenly. You gauge results; you quantify consistency, adjust application accordingly.

Are There Health or Safety Concerns With Concrete Dyes?

Yes. You should wear gloves, goggles, and a respirator when applying concrete dyes; make certain ventilation, read SDS data, and avoid skin contact. Check for volatile organic compounds, skin irritation potential, and disposal guidelines for waste.

What Restoration Options Exist After Fading or Wear?

You can restore faded or worn concrete with reapplication of dye or stain, resurfacing, or polishing; assess wear depth, test colors, choose compatible products, and follow manufacturer instructions, scheduling maintenance to maintain color stability and surface protection.

Do Colors Fade Differently Under UV Exposure?

Yes—colors can fade differently under UV exposure. In tests, pigments fade 20–40% faster than stains; dyes fade even more rapidly. You’ll notice brighter dyes lose vibrancy first, while stains typically resist UV longer, though both degrade.